The buildings and infrastructure of the not-so-distant future might look like they were dropped here from an alien planet thanks to the complex geometries and curvaceous surfaces robotic building technologies are able to produce. 3D printing in metal and concrete are among the biggest breakthroughs, but robots can also set building materials like bricks into place with unprecedented precision and produce prefabricated timber modules of the sort usually created by craftspeople. These 13 recent projects give us a glimpse at what we might be able to expect over the next couple decades.

3D-Printed Metal Bridge by MX3D

Looking like it was airlifted here from another planet, this metal bridge by MX3D took four robots six months to print and it’s almost ready to be set in place across one of Amsterdam’s oldest canals. “This bridge will show how 3D printing finally enters the world of large-scale, functional objects and sustainable materials while allowing unprecedented freedom of form,” says Joris Laarman. “The symbolism of the bridge is a beautiful metaphor to connect the technology of the future with the old city, in a way that brings out the best of both worlds.”

Prefabricated Load-Bearing Timber Modules Made by Robots

Think old-fashioned timber construction could escape the grip of digitalization? ETH Zurich proves that isn’t true with the creation of load-bearing timber modules prefabricated by robots in the company’s new laboratory. A single robot guides each beam as it’s sawed, and a second drills holes before the two robots collaborate to position the beams in the correct spatial arrangement. The result is a geometric structure that can be joined with other units to create a three-dimensional volume.

Robotically Fabricated Shanghai Gallery Facade

An undulating facade on an art gallery in Shanghai shows off a beautiful robotic masonry fabrication innovation as part of a recent renovation by Archi-Union. The facade’s curving protrusions couldn’t have been shaped with such precision by hand-laying techniques; a robotic mechanical arm arranged the old reclaimed bricks to ensure they’ll hold up to modern standards

3D Printed Formwork for Concrete

Looking almost like it was sculpted from clay and fired in a massive kiln, this truss-style support is actually made of concrete that was poured into a 3D-printed mold. The firm XtreeE programmed a robotic arm to extrude concrete into the shape of the outer layer of the structure, poured more concrete inside, and then filed the envelope away.

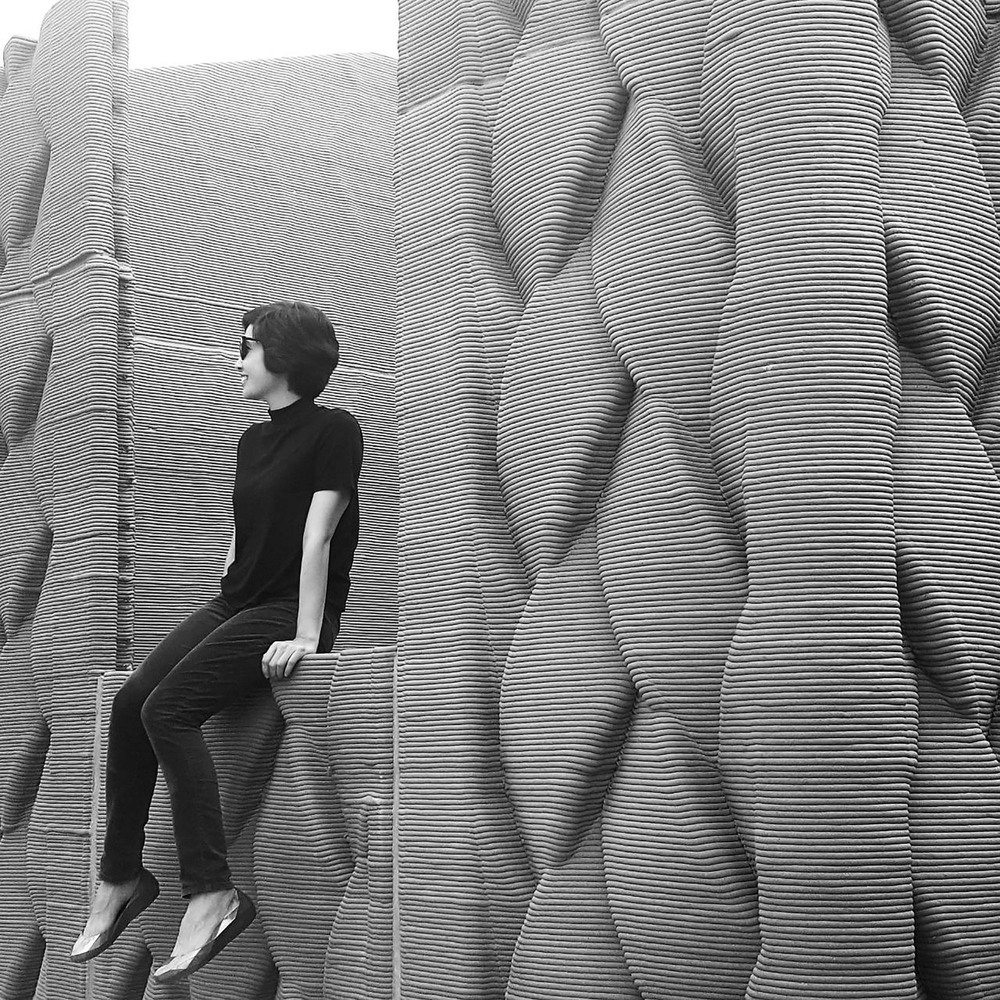

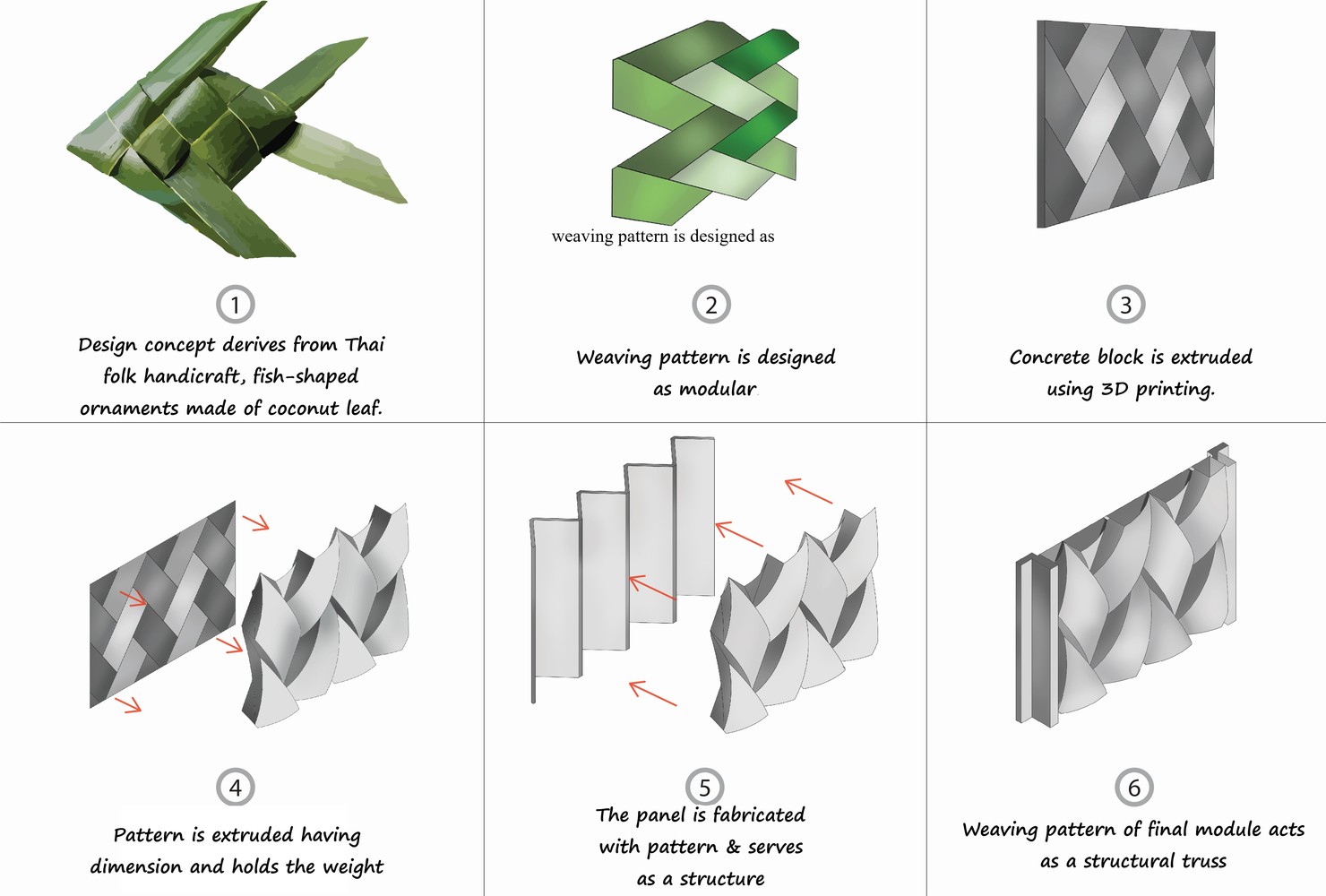

3D-Printed Structures Inspired by Thai Architecture

Traditional Thai handicrafts made of coconut leaves informed the shape of unusual 3D-printed structures by Thailand-based cement manufacturer Siam Research and Innovation Company (SRI.) “The weaving pattern is designed to be modular and implement in a concrete block,” says the company. “The concrete is being extruded using 3D printing to increase its dimensions as its weaving appearance. After printing, the 3D printing concrete panel is fabricated with the pattern and serves as as structure for holding its weight. After fabrication, the weaving pattern of final module acts as a truss for structural purposes.”