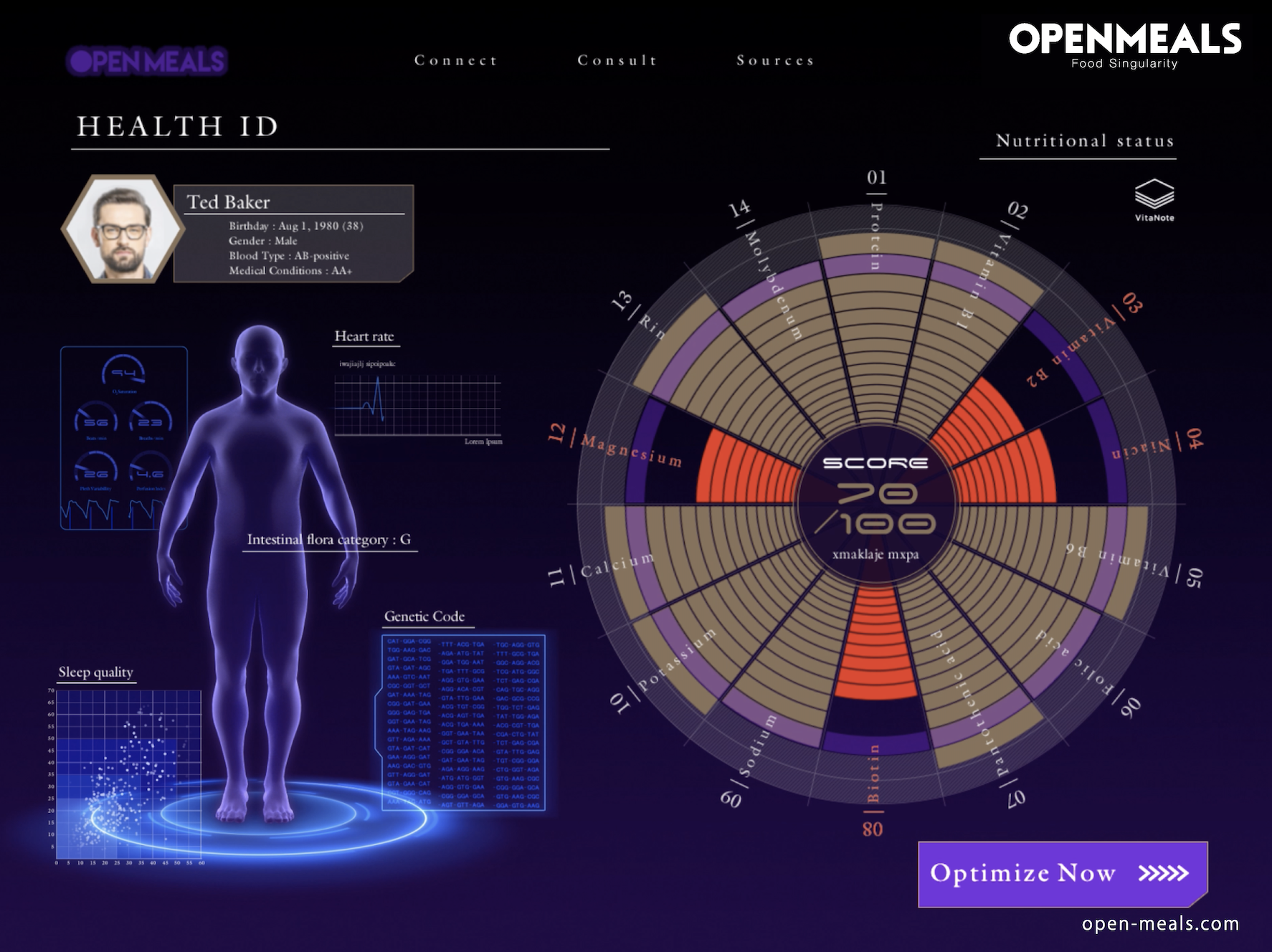

Not many sushis restaurants ask their patrons to provide urine and saliva samples upon entrance, but in our era of hyper-personalization, maybe we shouldn’t be surprised. From the Japanese company Open Meals, which debuted its complex 3D-printed sushi at the South by Southwest festival in Austin last year, comes a new range of high tech food that’s tailored specifically to the nutritional needs of its diners.

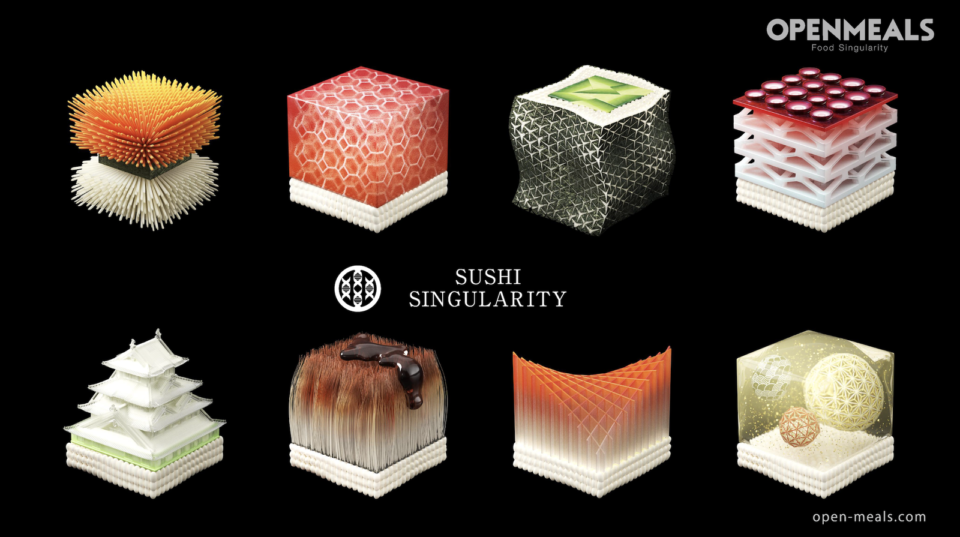

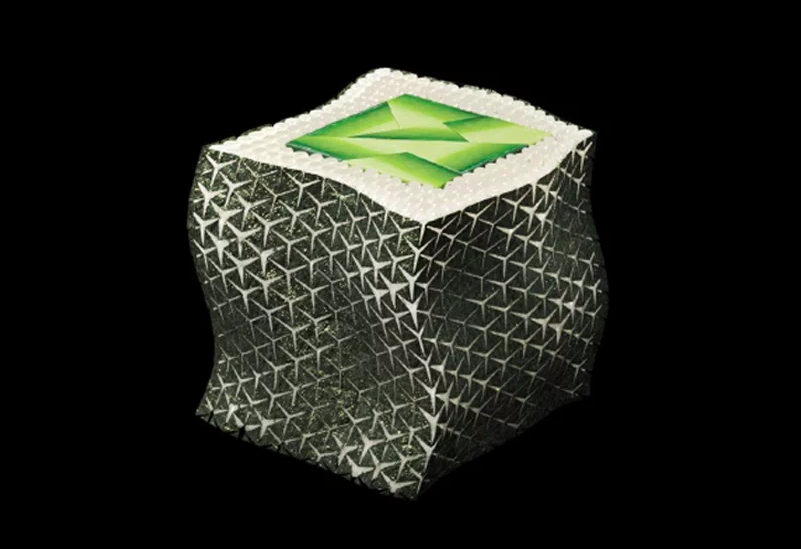

Set to launch in Tokyo next year, “Sushi Singularity” relies on a system of 3D printers, CNC routers, lasers, robotic arms and other components most often associated with industrial design to produce edible sculptures made of sushi ingredients. In each item on the menu, you’ll find common sushi elements like tuna, squid, eel and seaweed, but it’ll be in a form you’ve never seen before.

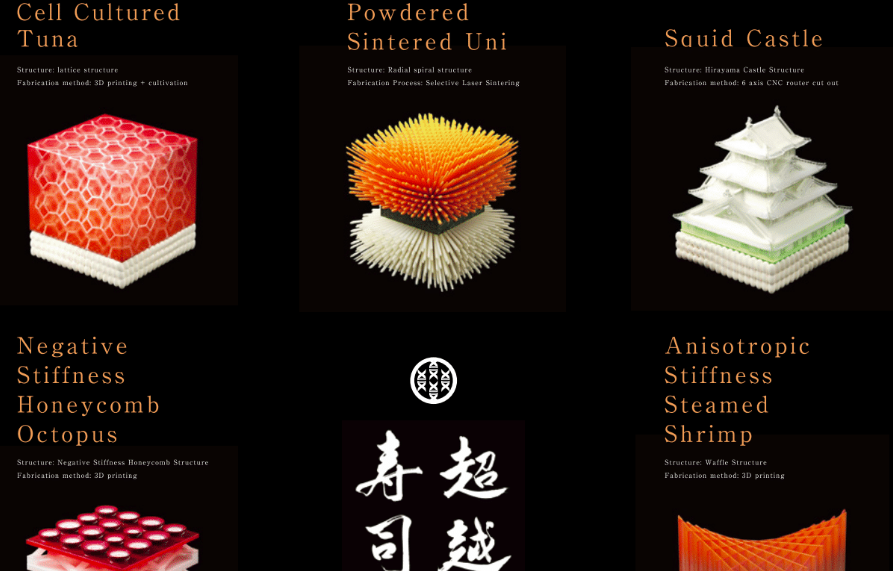

In order to mix each custom cocktail of nutrients in an aesthetically pleasing way through its machinery, Open Meals transforms each ingredient into a gel or paste. Menu items include “micro pillar saltwater eel,” “oze tick kappa roll,” “dash soup universe,” “anisotropic stiffness steamed shrimp,” “negative stiffness honeycomb octopus,” “cell cultured tuna,” “powdered sintered uni” and “squid castle.” When customers make a reservation, it’ll trigger the system to automatically send them a biodata kit in the mail, which requests urine, saliva and stool samples. The results will determine the exact creations you’re ultimately served when you arrive.

Here’s how they describe their process:

“Food Ingredient Cartridges: These will contain sustainable food ingredients such as seaweed and crickets, which are mixed with water, fiber, and enzymes for output. Nutrient Cylinders: 11 types of nutrients in cylindrical cartridges. Foods will be nutritionally optimized based on a Health ID. Alginate Fermenter: Produces spherical food in a chemical reaction between sodium alginate and calcium solution. Artificial light farm: Cultivates fresh vegetables in enclosed spaces through use of artificial light such as LEDs. Hot Water FDM: Items that cannot be formed at room temperature or in air can be realized by outputting them in hot water.”

“SLS: Laser Sintered 3D Printer. Powder-based raw materials are baked into specific shapes using lasers. FFM Control Interface: The brain of the entire machine, which combines various data to design and hyper-personalize food. Laser FDM: Thermolysis Laminated 3D Printer. The raw material is melted by heat and formed by stacking layers. Robot arm: The unit is equipped with an ultra-high precision arm. Chilled FDM: Outputs at ultra low temperatures to realize shapes impossible at room temperature. 6-axis CNC router: Cuts the material with a multi-axis router, enabling precise, elaborate modeling. Fermenter: Cultivates food ingredients in real time through precise management of water temperature and nutrients.”

Whether or not any of this actually sounds appetizing to you, the final result is certainly artistic, and perhaps a signal of what’s to come to the world of food in the near future as this kind of technology grows more accessible.