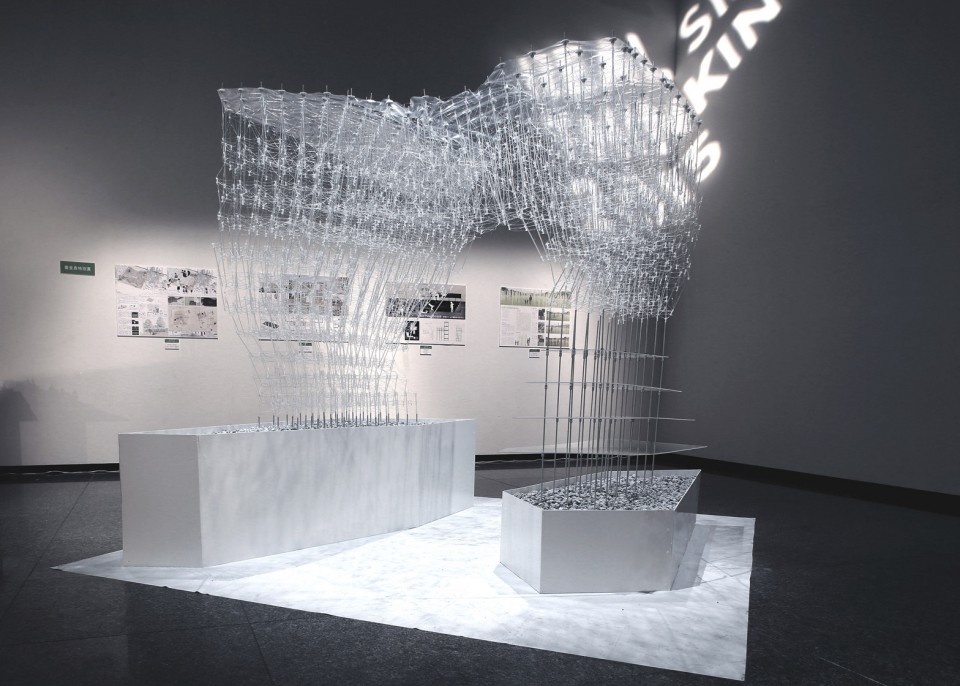

A group of students from the University of Tokyo have created the world’s first work of 3D pen-drawn architecture, extruding thermoplastic filament to generate a structurally-stable arch installation.

A digital tracking system helped builders connect rods with extruded supports, generating a lattice-like system of interconnected trusses (resulting in a kind of lightweight, smaller-scale space frame). The combination of rigid rods and fluid connectors helps the whole structural network, providing tension as well as compression capabilities.

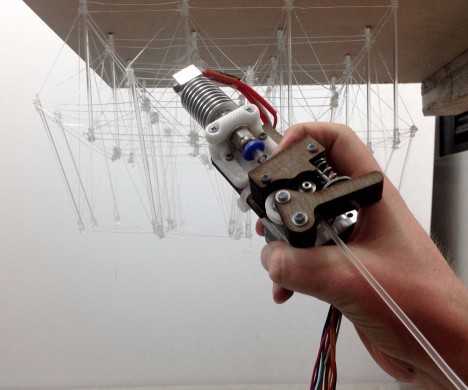

The handheld device enabling the extrusions operates much like a hot glue gun or static 3D printer, heating the constituent material and making it malleable before it hardens upon deployment. Unlike large-scale printers, this approach enables minute on-site work by anyone trained to use the machine, reducing costs and complexity.

“Technology has traditionally been used to automate and replace human labour,” design team member Kevin Clement, said in an interview with Dezeen. “The issue with this approach is that it fails to take advantage of human intuition during fabrication. We believe our approach can bridge the current dichotomy between machine and human-made production.”