Yet another candidate has entered the race for the world’s first 3D-printed house, with a mobile 3D printing factory in a shipping container that can produce the components on-site. Dutch studio DUS Architects plan to use the ‘KamerMaker‘ machine to print a full-size canal house in Amsterdam, one piece at a time. Work will start within the next six months.

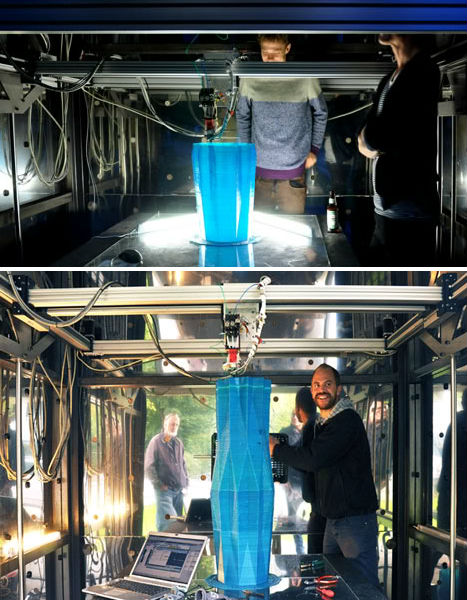

The other two other concepts currently in the works, ProtoHouse 2.0 and Landscape House, also aim to get started on their own 3D houses by this summer. What sets the DUS Architects concept apart is the fact that its printer is mobile. The KamerMaker is 3.5 meters high and easy to transport from one place to another.

The house, which will be built in a developing area along the Buiksloter-canal, will act as a hub for 3D printed architecture. DUS aims to print the entire facade this year, as well as the first room; other rooms will come later. Once complete, the first floor will become a ‘welcoming room.’ The entire construction site will be an event space to show off the capabilities of this technology.

The KamerMaker can print structures out of recyclable materials available on location, including biodegradable plastics, giving it great potential for emergency relief architecture. DUS plans to use polypropylene as well as plastic recycled on-site to build the facade and first floor of the house. Each room in the house will be dedicated to a certain type of research, including a ‘cook room’ where researchers will experiment with 3D printing in potato starch, and a ‘policy room’ where permits for printed structures will be discussed.