Leveraging the best features of available 3D printers and the materials they can print, this kit-of-parts approach opens up an amazing array of possibilities for do-it-yourself furniture construction and could be the beginning of a paradigm shift, informing the future of how we understand and make household objects.

Studio Minale-Maeda presented their Keystones system at Milan, using elegantly simple table and coat rack designs to show off the potential of this connective system.

Their core idea is that the larger wooden pieces can be flat-packed more easily for shipping. Customers can then complete the assembly process using included or locally-printed pieces. Still, the potential of this approach goes well beyond that system as such.

There is really no reason to limit the process to a ship-and-print combination. With a similar but open-source variant, would-be buyers could take off-the-shelf dimensional lumber and construct their own furniture effectively from scratch. Perhaps unintentionally, the simple and standardized shapes of the components shown here already suggest such potential implicitly – at most a few cuts would be needed for the table, if even that.

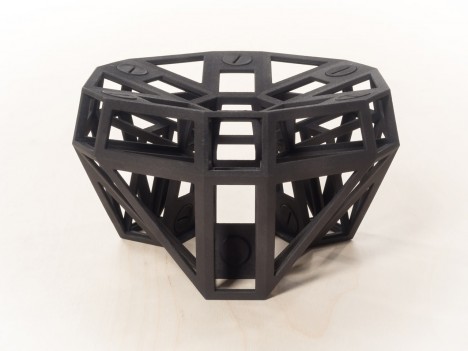

Regardless, the solution-as-presented is quite crafty, whatever its potential future might be – it leverages the strengths of 3D-printed plastic (rigidity with flexibility), uses strong triangular shapes for structural support (like trusses) and requires only the most basic tool to tighten the finished product (a screwdriver).