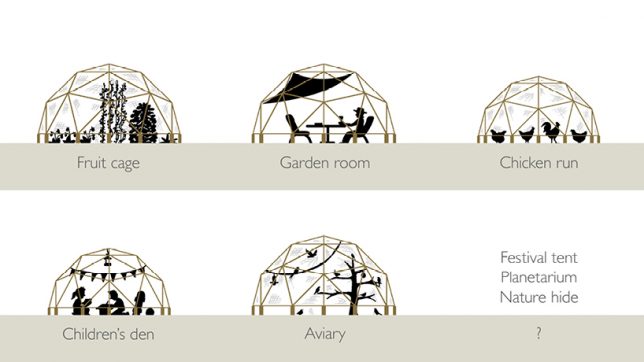

Reducing complexity and difficulty for would-be geodesic dome builders, this series of connective ‘Hubs‘ makes it possible for do-it-yourself types and even kids to collaborate on creating stable architecture.

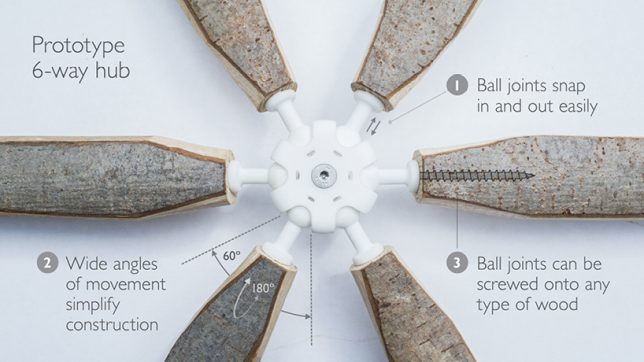

Connector rods are joined at a hub that acts as a ball joint. The connector ball screws into a piece of lumber then attaches to the node. A simple structure can use materials on hand to build a working dome in a matter of minutes, all assembled by just a few people.

Building geodesic domes from metal parts can be laborious and frustrating – each piece has to be perfectly bent to join the rest, and the resulting structure is extremely heavy. The Hubs system is much cheaper than buying (or bending) a conventional dome.

Chris Jordan and Mike Paisley started work on this system a few years ago and recently made it available for purchase after a successful round of crowdfunding brought it to market. Their hope is to make dome-building a more accessible, cheap and easy process for everyone.

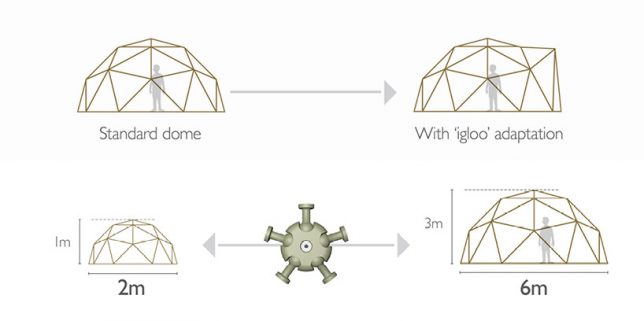

While wood and plastic are technically more durable, this approach lends itself to organic settings, creating wood structures that look appropriate in backyard settings and for temporary purposes or as ersatz tree houses. It is also more adaptable: cutting different lengths of wood lets users scale their dome more easily than with metal or plastic. And it is more flexible, too: the joints can bend and give, as can the wood, making the construction more forgiving.