3D Printed Illuminated Glass Columns

These 3D printed glass columns debuted at a LEXUS show at Milan Design Week, created by designer, inventor and professor of the MIT media lab Neri Oxman. These oversized glass pillars have LED lights integrated into them to cast patterned shadows on the floors.

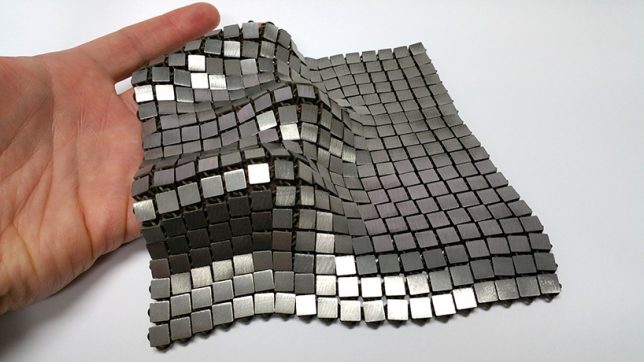

‘4D’ Printed NASA Space Fabric

Designed to act as ‘chain mail’ that can protect astronauts from meteorites during their missions in space, this ‘4-D printed’ metallic material was developed by NASA’s jet propulsion laboratory. It looks like a bunch of individual metal squares strung together, but in reality, it’s all one piece, capable of extraordinary strength, foldability, heat management and reflectivity.

“We call it 4D printing because we can print both the geometry and the function of these materials,” says project leader Raul Polit Casillas. “If 20th century manufacturing was driven by mass production, then this is the mass production of functions.”

Biodegradable Footwear Printed on Demand

20 billion pairs of shoes are manufactured every year, and 300 million are thrown away in the same time. Two Polish students envision a better, more sustainable way to meet demand without trashing the planet with ‘Shoetopia,’ a 3D-printed biodegradable sneaker. Highly customizable via an app, the shoe design file can be sent to a local 3D printing center or privately owned printer for production, and is made from flexible, biodegradeable filaments and natural textiles without a need for glue. The app even lets you measure your foot for a perfect fit.

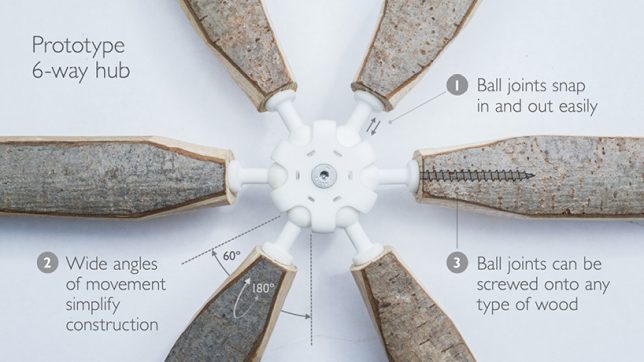

3D Printed Hubs for Geodesic Domes

One example of how 3D printing is already making it easier to build full-scale architecture is the ‘Build with Hubs’ kit, providing users with simple, easy-to-use joints for geodesic domes. All you need are wooden sticks to create the framework. It’s compatible with any kind of wood, and you can adjust it to whatever size you want by changing the length of your sticks, creating chicken coops, play structures, aviaries, fruit cages or even igloos.